Friction Welding

Friction Welding and Its Advantages

Friction welding offers an efficient and sustainable method for joining metal components, ensuring high strength and reliability of the joints.

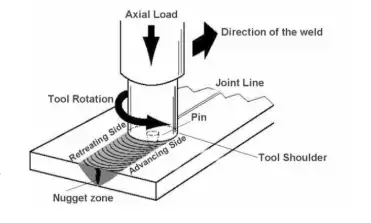

Friction Stir Welding

The principle of FSW technology

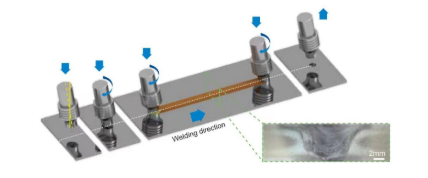

Friction stir welding (FSW) is a modification of the traditional friction welding and machining process.

Advantages of Friction Stir Welding

FSW technology offers significant improvements in quality, efficiency and cost-effectiveness

Metallurgical advantages

- Solid-state process

- Low deformation of the part

- Good dimensional stability

- No loss of alloying elements

- Excellent metallurgical properties

- Fine microstructure

- Absence of cracks

Environmental advantages

- No shielding gas

- No post-weld cleaning

- Eliminates grinding waste

- Eliminates degreasing solvents

- No consumables required

- No harmful gases

Energy advantages

- Improved use of materials

- Weight reduction

- Only 2.5% of the energy used in laser welding

- Reduced fuel consumption

- Applications in lightweight vehicles and ships

Advantages over other technologies

The superiority of FSW technology compared to traditional welding methods

FSW vs Fusion Welding

- Improved mechanical properties

- Reduced deformation

- Lower defect rate

- Preserves the base metal chemistry

- Simplifies welding of dissimilar alloys

- Fewer process variables

- Eliminates consumables

- Reduces health risks

FSW vs Riveting

- Improved mechanical properties

- Reduced production time

- Increased load-bearing capacity

- Improved fracture resistance

- Eliminates consumables

- Less operator dependence

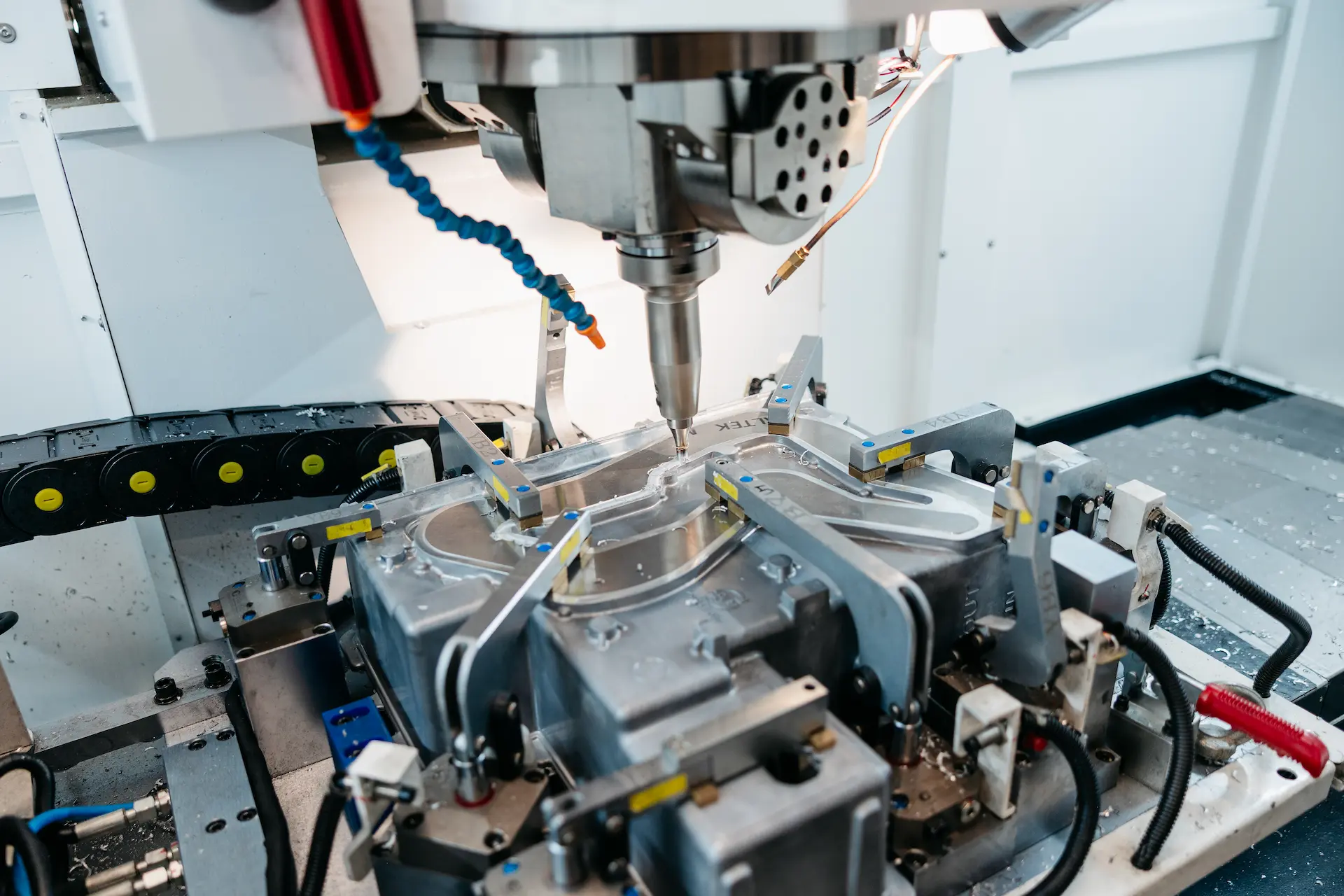

Section for applications or diagrams?

Discover the variety of applications and the high quality of FSW technology

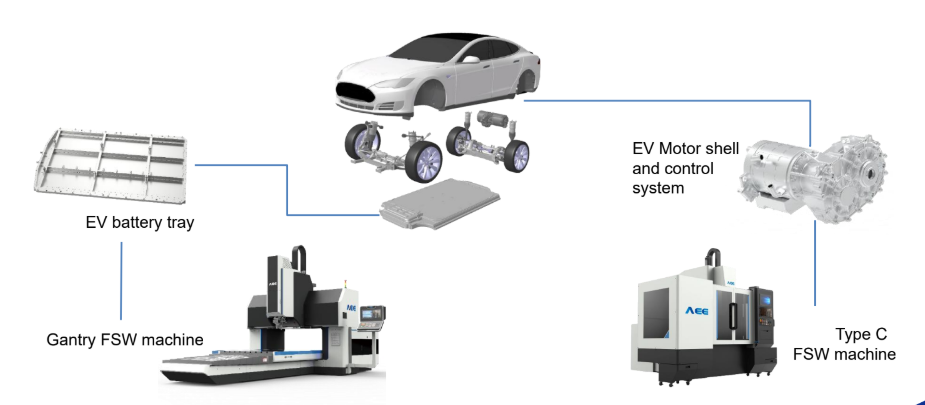

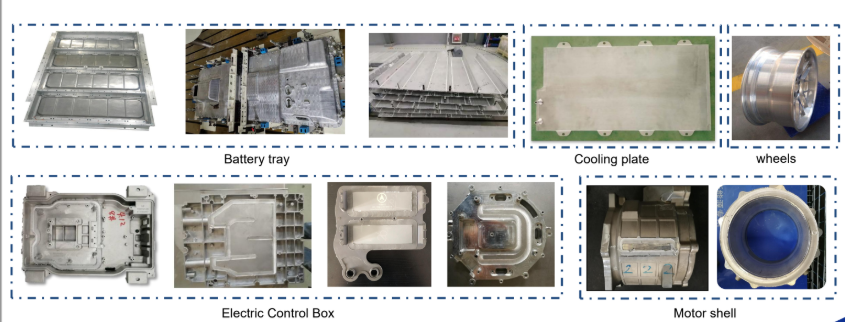

Applications in EV components

High-precision welding of aluminium panels for the aerospace industry with excellent joint quality and strength.

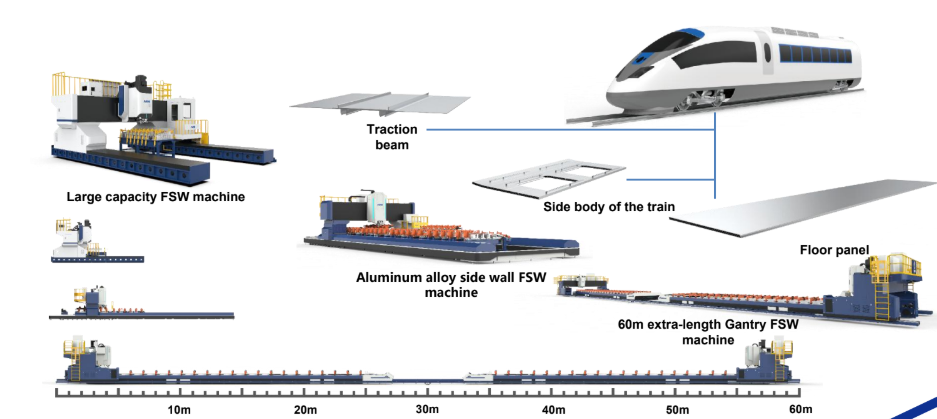

Applications in rail transport

FSW technology for shipbuilding – welding of large aluminium structures with unrivalled corrosion resistance.

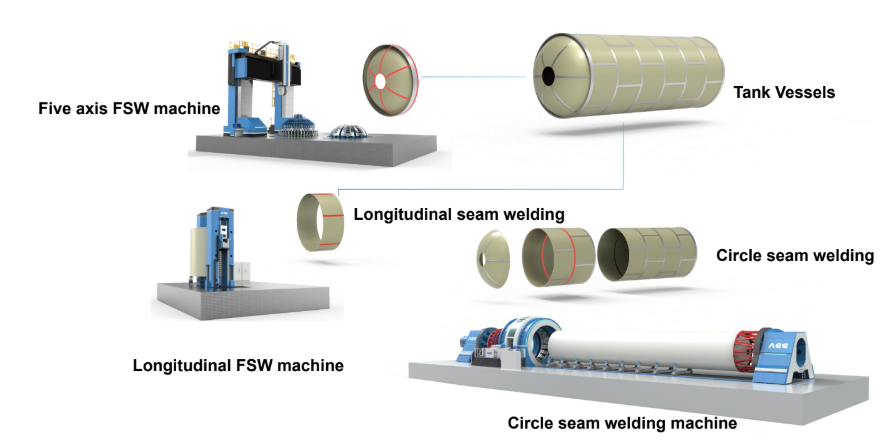

Applications in marine shipbuilding

Lightweight and strong aluminium components for the automotive industry, providing better fuel efficiency.

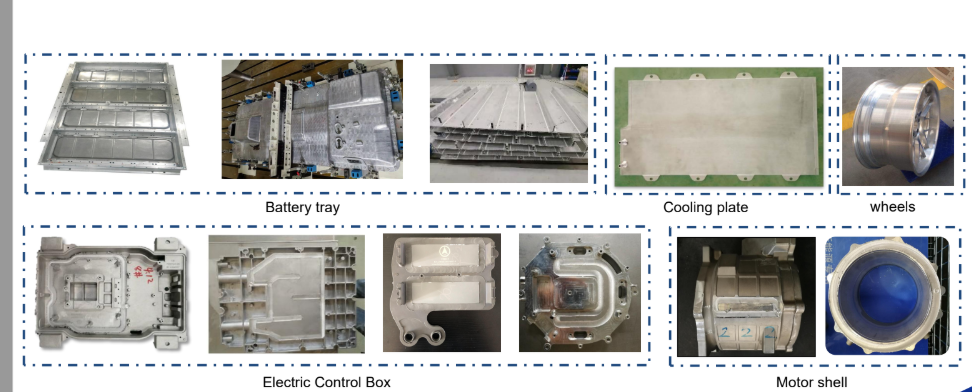

Applications in batteries, automotive industry and electrical engineering

High-speed trains and metro cars with FSW-welded aluminium structures for maximum safety and efficiency.

FSW for finished components and modules

Consistent quality when welding and finishing parts for transport, energy, and industrial products.

- Clean seams with minimal deformation on large panels.

- Works with aluminium profiles and multi-part assemblies.

- Process tuned for serial production with repeatable results.

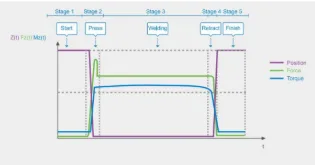

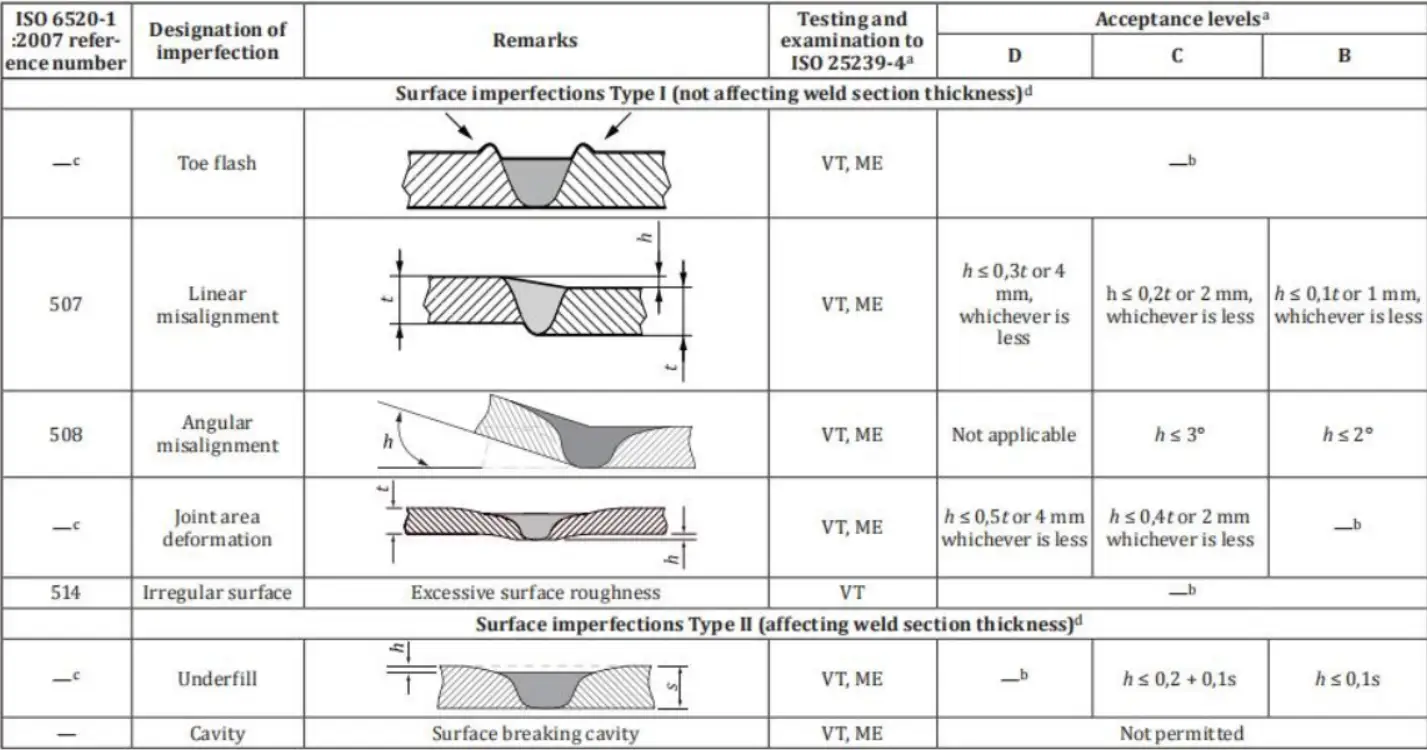

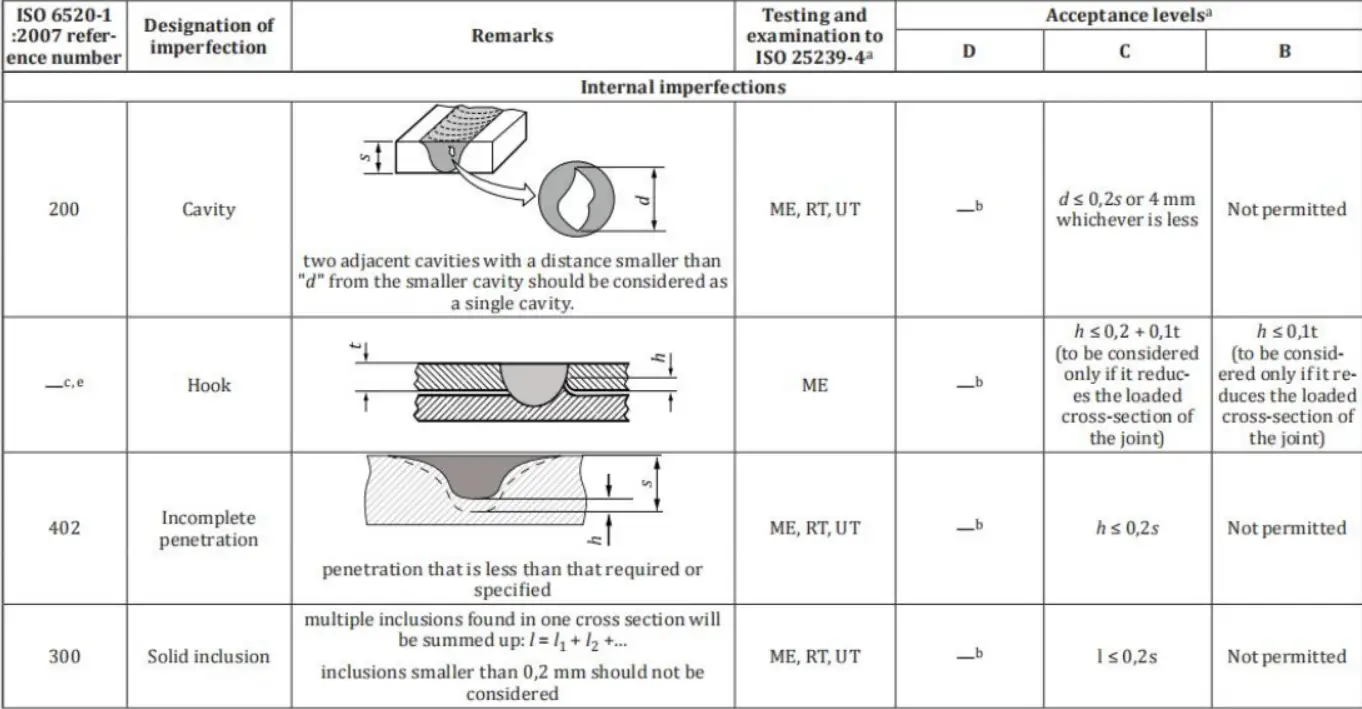

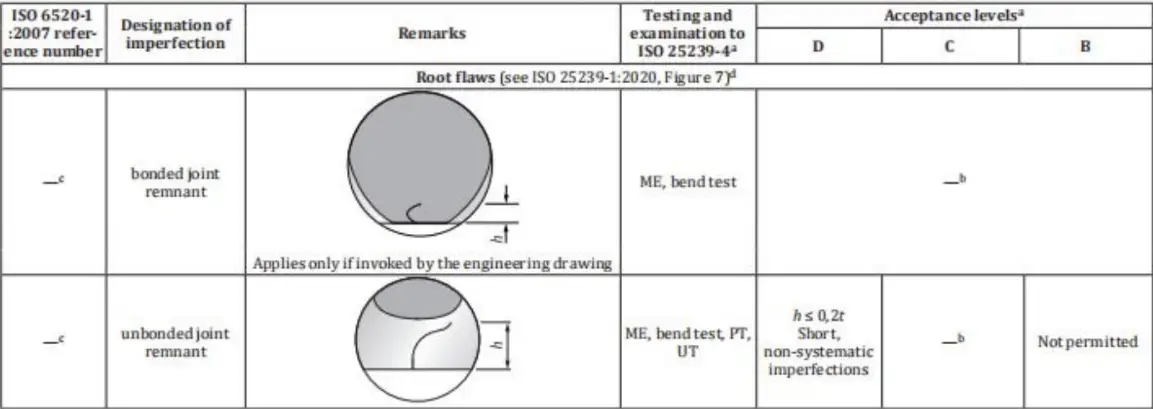

Quality standards in FSW

Showcasing how we validate and monitor the quality of every FSW process.

See our FSW machines and quality control

Explore the equipment that delivers consistent results and the procedures that validate every step of the process.