Quality Management

Statistical Process Control

- Pareto analysis

- Scrap rate

Raw Material Inspection

- Incoming material inspection against approved specifications and PPAP.

- Sampling control according to defined plans.

Production and Quality Planning

- APQP product and process planning.

- Manufacturing feasibility analysis.

- Preparation of PFMEA and Control Plan

In-Process Quality Control

- Real-time monitoring of critical parameters.

- SPC control of special characteristics.

- Cp / Cpk

Final Product Testing

- Final inspection against approved criteria.

- Functional and/or dimensional testing.

- Conformity confirmation before shipment.

- Non-conforming product management.

Analysis, improvement, and feedback

- Defect and claim analysis.

- Root Cause Analysis.

- Corrective actions and FMEA and Control Plan updates.

- 8D Report

Quality Control Machines Used in Aluminum Die Casting

Modern measurement and analysis systems developed specifically for aluminum die casting processes.

X-ray Machine

Source type: integrated X-ray source. Object thickness: Fe 3-5mm, Alu 2-20mm.

Model: Polyspek jnr

PolySpek Jnr is a benchtop CCD spectrometer from ARUN Technology, pioneers in metal analysis with CCD technology.

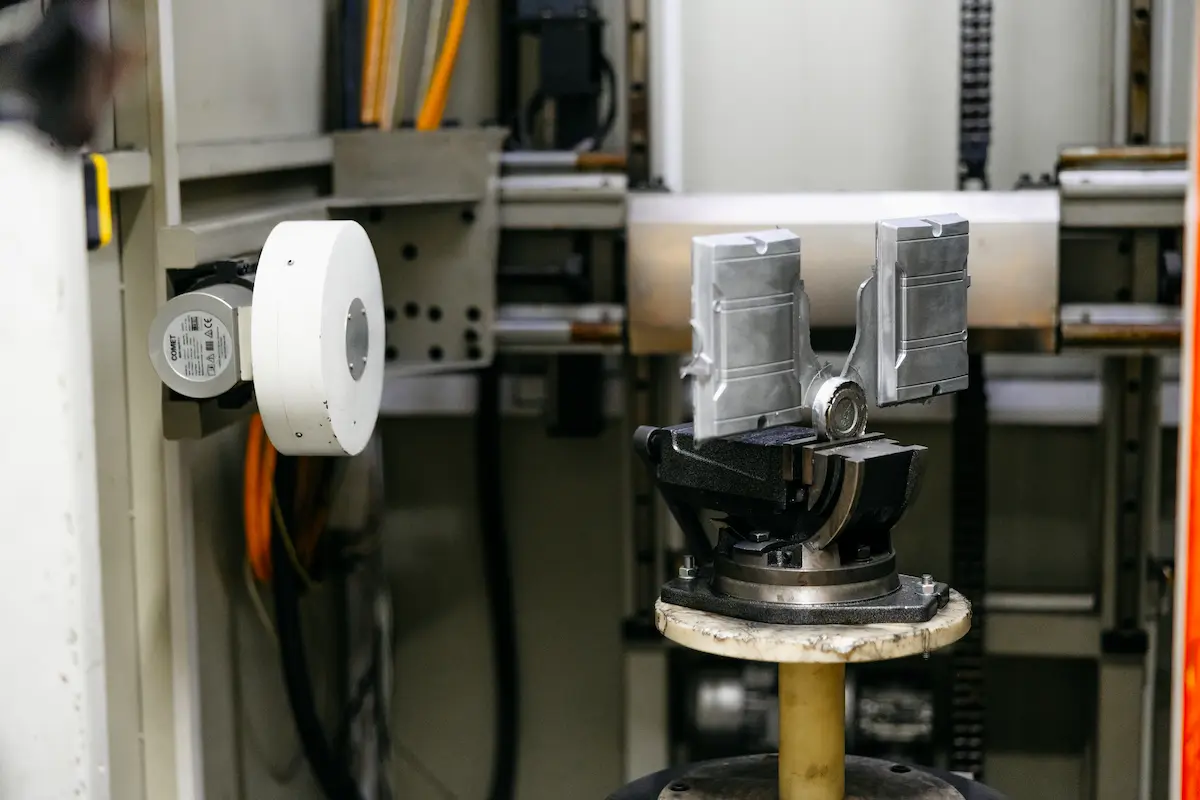

3D Measuring Machine with Motorized Head

3D coordinate measuring machine (CMM) with fully motorized, high-precision 5° measuring head, compatible with a wide range of CMM systems.

X-ray Machine

X-ray Image Control Room

Quality Control Machines for Powder Coating

Modern measurement and analysis systems developed specifically for powder coating processes.

DR1900 Portable Spectrophotometer

Rugged, ultra-portable spectrophotometer for field water analysis.

ComBi D3 / D3plus — Non-destructive Coating Thickness Gauge

Non-destructive coating thickness gauge with automatic mode recognition and one-hand probe operation.

Cross cut — cross-hatch adhesion test

Manual cross-hatch adhesion test tool for fast, standardized coating adhesion classification.

Quality Control Machines for Mechanical Processing

Modern measurement and analysis systems developed specifically for mechanical processing.